K-SERIES:

To do a K-series, you can for the most part follow the B-series guide step by step. The following photos and explanations are what need changed. Beyond that, it's the same basic principle. Just always take your time and keep things in order and make sure they get back together correctly.

Tools:

Same as B-series for the most part.

14mm allen socket (1/2")

8mm allen socket (3/8")

Small pick or screwdriver (possibly)

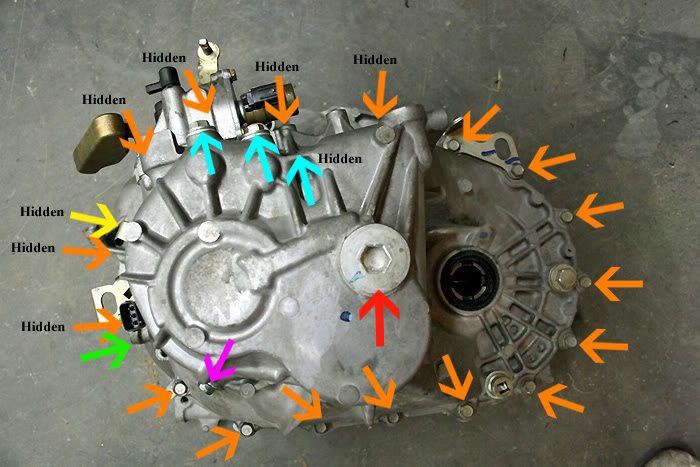

Here is the overall bird's view of the K-series. Yes, it's opposite the B-series. Diff to the right and what not.

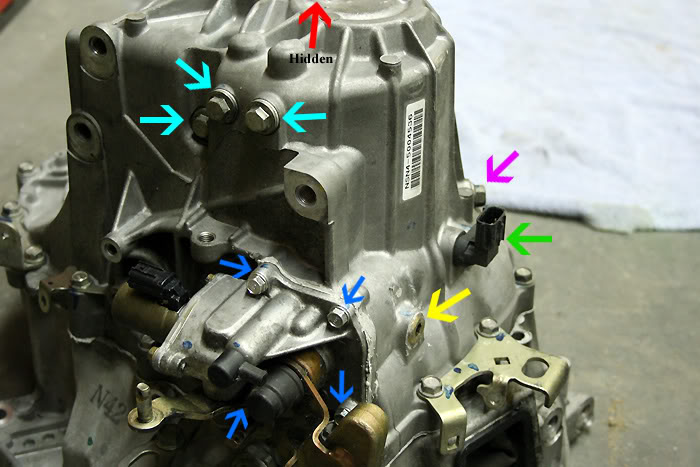

These are the majority of the bolts you will be removing. There are still 17 12mm transmission case bolts (ORANGE ARROWS). As a general rule, remove these bolts last during teardown. During rebuild, these go in first. For the other bolts, it's safe to remove them in any order you wish for the most part. The shift fork bolts retaining the balls and springs (TEAL ARROWS) are still there as well, excepte there are three now, instead of two. There is also the standard 14mm reverse idler shaft bolt (PURPLE ARROW). The bolt which covers the c-clip is now a 14mm allen bolt (RED ARROW) rather than the 1/2" square bolt of the B-series.

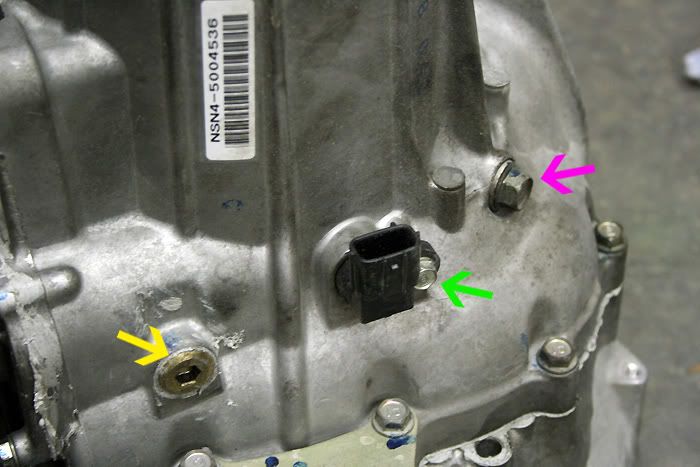

For the shift change assembly, which is drastically different, you will remove 5 bolts. There is one 8mm allen bolt (YELLOW ARROW), as well as four 10mm bolts (BLUE ARROWS and HIGHLIGHTS). Once these are removed, this entire piece will simply pull out. It may stick a bit if there is Honda Bond on the mating surface.

NOTE: In the 6-speed models with the magnetic speed sensor reading from the 3rd gear (2005-2006 6-speed transmissions exclusively I believe), you must remove a 10mm bolt and pull the speed sensor out before lifting up the casing. More than likely, if you don't, you will severely damage the magnet as it is pulled up past the 3-4 and 5-6 synchronize sleeves.

The only other bolts are inside the casing. There are two 10mm black bolts which hold the reverse change assembly to the casing, just like in the B-series.

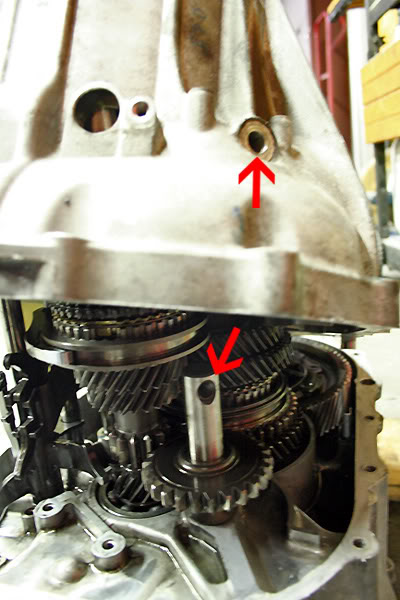

This is the c-clip design - open in the photo. The case is alot more shallow, but the c-clip in general is much easier to open up than a B-series.

There is also an annoying difference with the reverse idler shaft in the K-series transmissions. The shafts do not have the locating pin for the case, even though the case has a location for that pin. :scratches head: Be sure to line up the bolt hole in the shaft to its rough location on the transmission case (RED ARROWS). Even if it is a little off, you can still use a pick or small screwdriver to get in there and rotate the shaft around so it all lines up. The first K-series I rebuilt I never took notice to this, and when I went to thread the reverse bolt back in, the hole in the shaft wasn't even in sight! With a pick, I still managed to rotate it around so that I didn't have to separate the case and possibly do any more work to the sealant.